IsoFlock is made of the environmentally friendly Comprex foam (regenerated). Comprex foam is manufactured as a regenerated polyether material (also called bonded foam). The material has good soundproofing properties, as well as sound absorbing properties. Comprex foam is manufactured under high pressure, and through this special process, foam materials with high densities from 80 - 230 kg/m3 can be created.

We would love to inspire you, so please take a look at some of our latest solutions by clicking on the gallery images.

The material is primarily used as an acoustic cladding in maritime engine rooms, compressors, generators, fans, turbines, pumps or similar.

In engine rooms on ships, IsoBoat is typically installed directly on steel surfaces, between bulkhead sections and bearers, with the aim of reducing and encapsulating engine noise, as well as reducing the possibility of noise propagation.

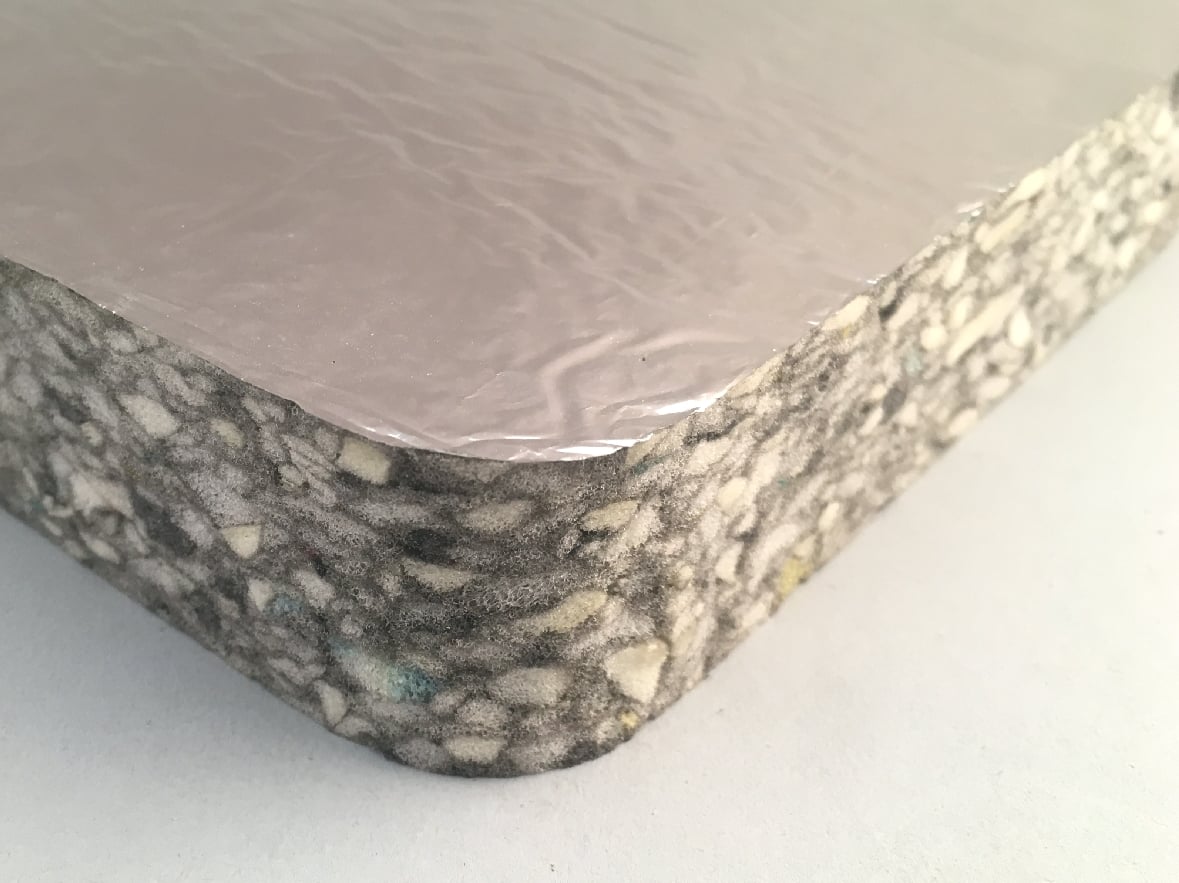

If the product is to be installed in particularly humid environments, we can offer to apply a special edge seal or to add an aluminium foil edge.

As an alternative to IsoFlok, we can offer the highly efficient IsoBoat, which is a sandwich construction consisting of B028 mm.

The brand IsoFlock is produced by the company ISOVER, which specializes in manufacturing various types of insulation materials. This specific insulation material is made of Comprex foam, which is a regenerated polyether material also known as bonded foam.

Bonded foam is a synthetic material manufactured from recycled polyether foam or foam waste, creating a durable foam structure through adhesive or heat treatment. This material is known for its ability to absorb shock and reduce motion transfer.

Comprex foam or bonded foam is produced under high pressure, allowing for the creation of foam material with densities ranging from 80-230 kg/m3. This provides the flexibility to find the desired density of insulation material required for specific tasks.

IsoFlock possesses an open cell structure, meaning that there are small openings within the material at a cellular level. These openings allow various liquids to move through the material. The open cell structure is also suitable for sound insulation, as it captures and reduces sound waves upon impact with the material.

The material's open cell structure offers excellent sound absorption and soundproofing properties, making it versatile for insulation in different settings.

IsoFlock is manufactured from recycled materials, giving it an environmentally friendly aspect. When combined with its high insulation capabilities, which can help reduce energy consumption in heating applications, IsoFlock presents a sustainable alternative to traditional insulation materials such as fiberglass.

Due to IsoFlock's lack of harmful chemicals or particles like fiberglass, it is considered a healthy and eco-friendly material to work with and use for insulation purposes.

IsoFlock is commonly used as insulation material for new constructions and renovation projects in existing buildings to optimize insulation effectiveness and minimize heat loss.

Additionally, due to its excellent sound absorption and insulation properties, the material is utilized as cladding for marine engine rooms, compressors, generators, fans, turbines, pumps, and similar equipment.

As mentioned, IsoFlock is used as cladding for marine engine rooms, indicating its approval for marine use according to the ISO 9094-1 and ISO 9004-2 standards. This insulation material meets various standards and requirements necessary for safety measures in a maritime environment.

The material's fire-retardant qualities, combined with its heat insulation and soundproofing capabilities, help reduce the risk of fire on board. Treated with fire retardants, IsoFlock is highly resistant to fire and can prevent or delay the spread of flames.

At B6-industri, we have extensive experience in producing soundproofing and sound-absorbing solutions using IsoFlock. Our solutions include edge sealing, vibration damping, as well as surface and foil applications.

For installations in highly humid environments, we offer special edge sealing or aluminum foil edging, which enhances heat reflection and improves the material's isolation capabilities.

We offer IsoFlock in densities ranging from 80-230 kg/m3. You can choose to receive the material in full sheets or rely on our assistance to precisely cut it according to your specific measurements.

As an alternative, we recommend the Danish brand Isoboat, specializing in insulation solutions for boats. Isoboat utilizes a sandwich construction consisting of B028 mm, typically mounted directly on the steel plates between the boat's frames and stringers. This reduces and encapsulates engine noise while preventing noise propagation.