The product term acoustic foam covers a variety of products whose primary purpose is to dampen and absorb sound in different contexts. It can be manufactured in different foam types - such as polyether foam or polyurethane foam.

While polyester foam has an open cell structure and is a fairly flexible material to work with, polyurethane foam, due to its higher density, is a more rigid material to mold, but is also more resistant to deformation caused by impact and shock.

Both polyester foam and polyurethane foam have good acoustic properties that offer a wide range of possibilities for improving room acoustics. Both materials are excellent at absorbing unwanted noise, significantly reducing reverberation time.

Acoustic foam has many different applications. From recording studios and cinemas to offices and conference rooms, this type of foam is used as an insulating material to improve sound quality by absorbing and filtering unwanted noise.

The foam can also be used as acoustic cladding in cabs, engine compartments, compressors, generators, fans, turbines, pumps or in similar applications where noise reduction and acoustic improvement is desired.

With its ability to eliminate or reduce unwanted noise, acoustic foam is an important element in improving or maintaining a healthy and productive working environment. A noisy work environment can have far-reaching physical and psychological consequences for the people who work in such environments on a daily basis.

By doing your best to reduce noise nuisance related to the work environment, you can achieve better employee well-being, and as a result, a possible improvement in employee concentration and productivity.

As part of our wide range of foam products, we offer Flexfoam B028, which is the best sound-absorbing yet most flexible foam variant you'll find in our range for noise reduction.

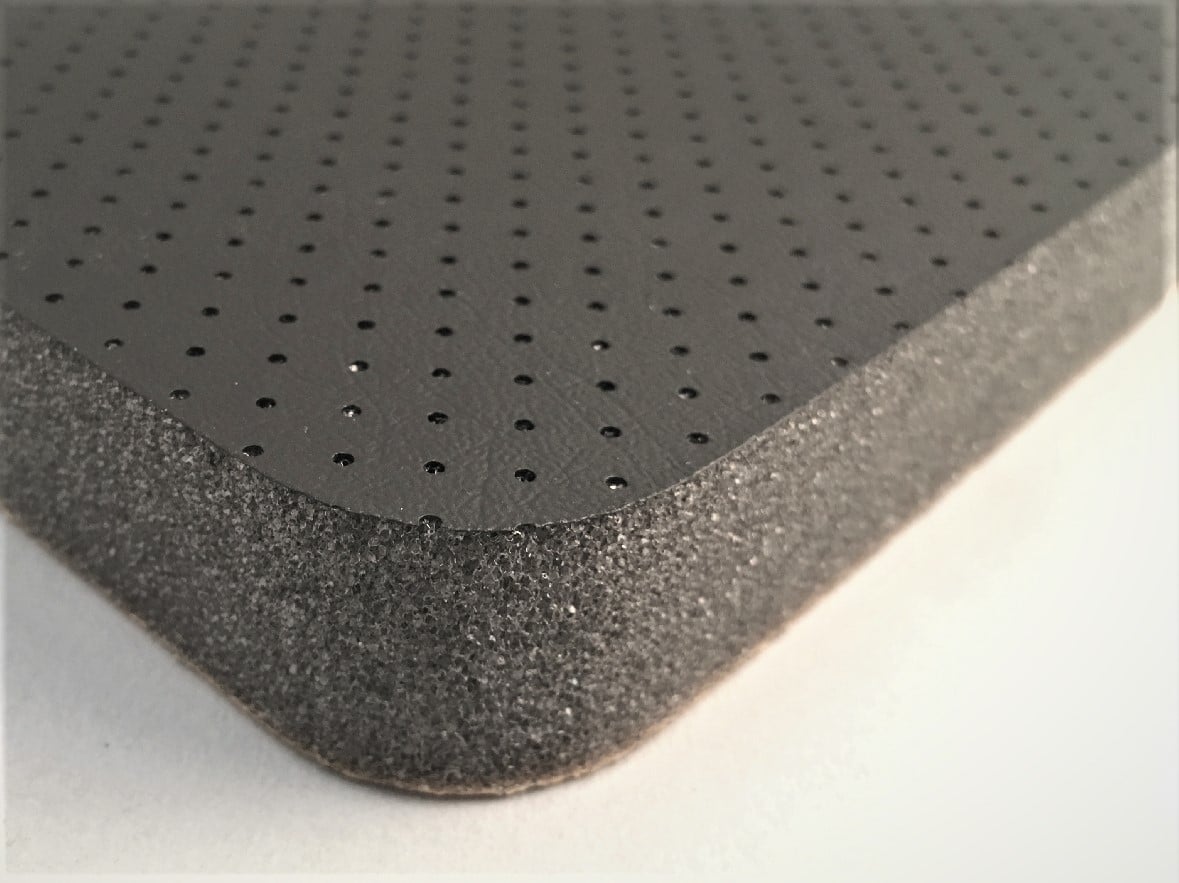

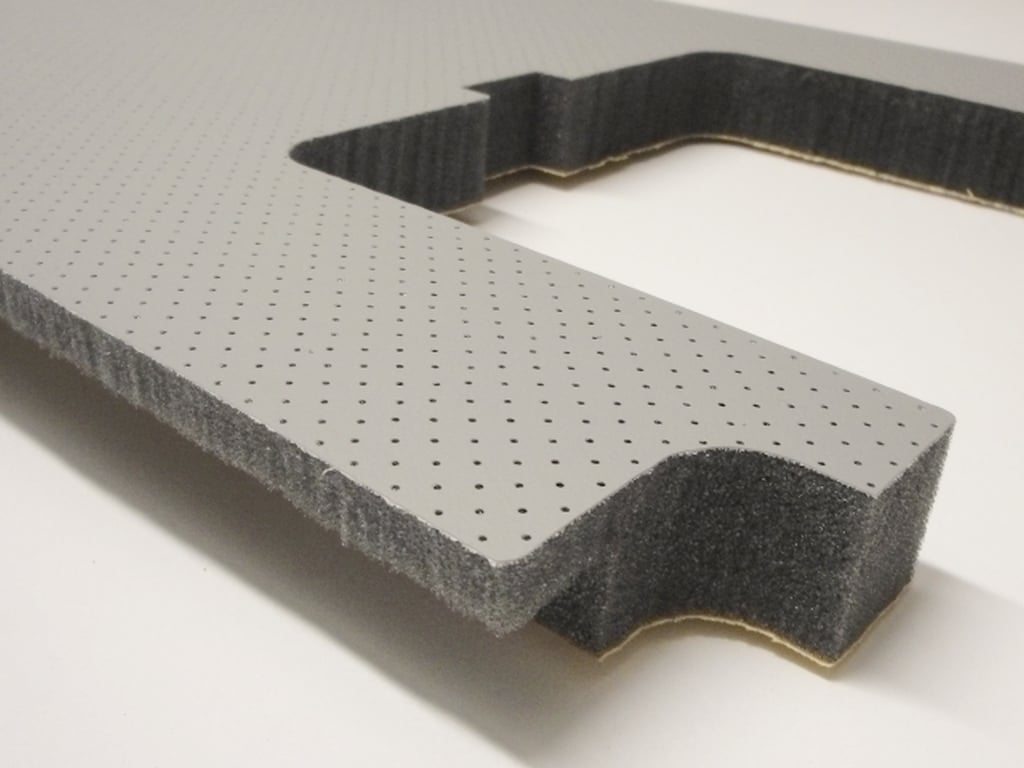

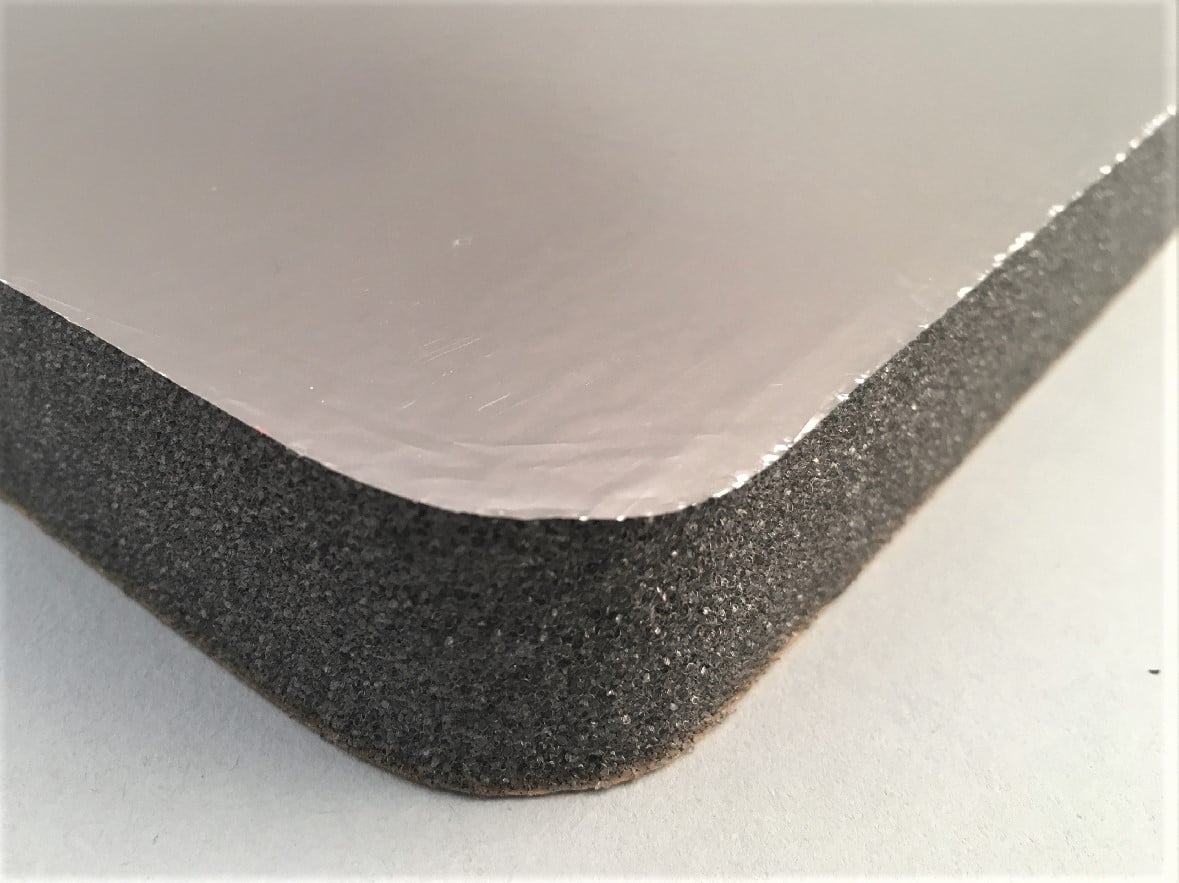

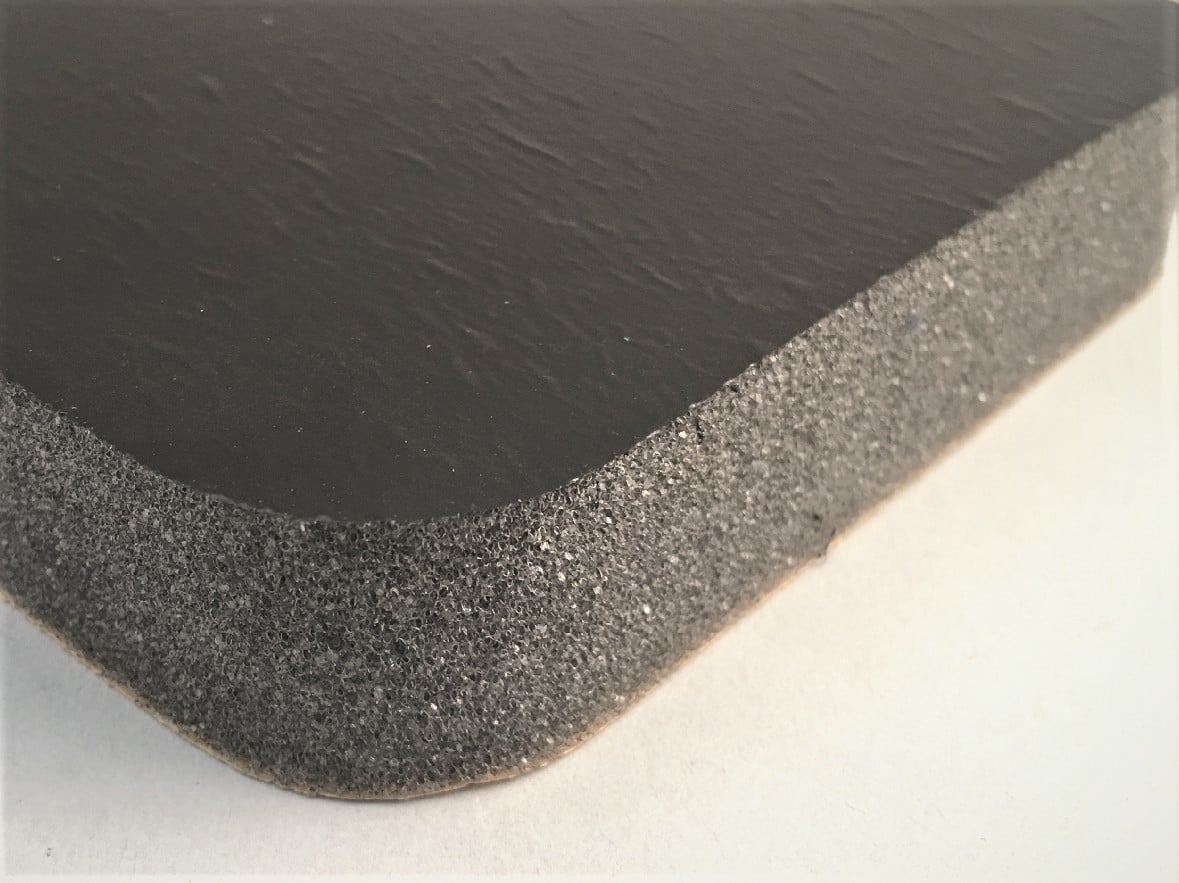

Made from polyurethane foam, Flexfoam B028 allows noise to easily penetrate and then re-reflects only a fraction of the original noise. The material is particularly useful as acoustic cladding in various applications, and you are free to choose whether you want to purchase the material in whole sheets or as cut pieces to suit your exact purpose.

You can also choose which surface you want to laminate the acoustic foam to, and you can choose whether you want the material with or without adhesive.

In some applications, Felxfoam B028 does not meet the different expectations and requirements our customers have for the foam. In such cases, we naturally have some alternative products, such as C033 and C035, which can meet other requirements and standards.

While Flexfoam B028 is a polyurethane foam, the other two variants mentioned above are both made of polyester foam, which gives them different qualities and applications.

Flexfoam C033 is a good sound absorber for acoustic use in places where the UV stability of the material is required. Compared to B028, this type of acoustic foam does not require a laminated film to be UV-resistant, for example.

If you need a foam type that is both UV-resistant and meets various fire classifications, you should take a closer look at Flexfoam C035.

At B6-industri, we are experts in foam, and we sell a wide range of different products for sound absorption and noise reduction. If you need advice and guidance on choosing the type of acoustic foam that best matches your sound absorption and noise reduction needs, please contact us and we will help you find the perfect match.

We would love to inspire you, so please take a look at some of our latest solutions by clicking on the gallery images.

Typical benefits of PUR (polyurethane)

PUR is typically used for solutions such as: